Spruewell

Well-known member

- Joined

- Mar 6, 2021

- Messages

- 668

- Reaction score

- 435

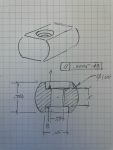

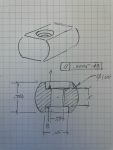

Working on a part that starts 1" round 303 Stainless. I need to put flats on either side and then counterbores as shown. I'm running a HAAS VF2 with SRT210 4th axis. I also have 5C indexer. My VF3 with the good 4th axis is tied up with another job. I'm not sure I trust the SRT210 to consistently hold the .0005 parallel tolerance I need. Concentricity between the bores is not as critical

Any suggestions?

Any suggestions?