OK, I'm trying to sort out the best way to pull 1-3/8" steel bars. The Royal cut-off/puller is sweet but too rich for my blood.

Other than the spring loaded cup things, is there a middle ground in pullers?

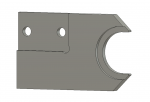

Part of me says just make up a gripper of my own with some springs and jaws, but maybe there's another route?

Other than the spring loaded cup things, is there a middle ground in pullers?

Part of me says just make up a gripper of my own with some springs and jaws, but maybe there's another route?