RJT

Member

- Joined

- Apr 28, 2021

- Messages

- 45

- Reaction score

- 39

- Location

- Greensboro, North Carolina

- Website

- www.progtool.com

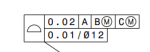

Quoting some plates that have a call out on the bottom surface (parallelism symbol) // .012/100 to surface A (which is the top surface) . The only thing that I can guess is the .012 flatness applies over 100 mm? The part is 400 mm square and 40 mm thick. I've never seen a limiter used like this, am I on the right track?