Spruewell

Well-known member

- Joined

- Mar 6, 2021

- Messages

- 669

- Reaction score

- 437

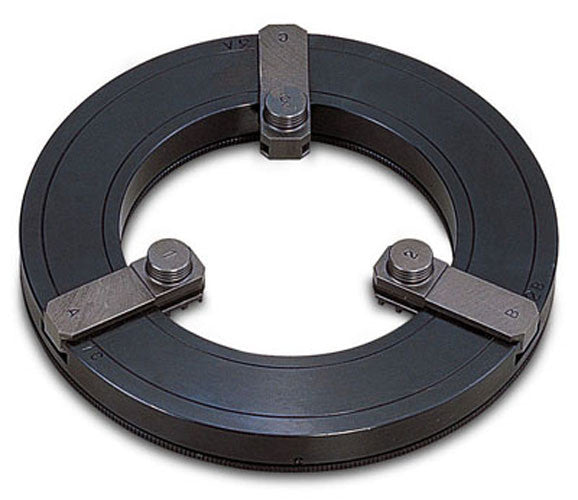

Samchully 10” chuck in my Hyundai SKT28LM is having an issue with runout. However, it isn’t consistent. I’m running soft jaws and the runout is changing +/-.005 depending on how the chuck is oriented

It had runout when I first got it. I removed it, cleaned it and reinstalled it. It still had runout that I was never able to correct. I tore it down and reassembled it several times and even tried rearranging the jaws.

It had runout when I first got it. I removed it, cleaned it and reinstalled it. It still had runout that I was never able to correct. I tore it down and reassembled it several times and even tried rearranging the jaws.